|

|

|

(*)

ASTM :E-2157-01 (*)

ASTM :E-2157-01 |

| |

The

C.T. Meter (Circular Track Meter) is a road surface macrotexture

profiler, in which a CCD (Charged Coupled Device) Laser Displacement

Sensor is used. It is designed to measure on the same circular

track on which the D.F. Tester measures

the dynamic coefficient of friction. There are various methods

to characterize road surface macrotexture profiles. The C.T.

Meter reports the MPD (Mean Profile Depth) and the RMS (Root

Mean Square). The IFI (International Friction Index) can be

computed using the C.T. Meter in combination with the D.F.

Tester. The

C.T. Meter (Circular Track Meter) is a road surface macrotexture

profiler, in which a CCD (Charged Coupled Device) Laser Displacement

Sensor is used. It is designed to measure on the same circular

track on which the D.F. Tester measures

the dynamic coefficient of friction. There are various methods

to characterize road surface macrotexture profiles. The C.T.

Meter reports the MPD (Mean Profile Depth) and the RMS (Root

Mean Square). The IFI (International Friction Index) can be

computed using the C.T. Meter in combination with the D.F.

Tester.

(*) There are also several

documents by which that's transcribed as Circular Texture

Meter.

This instrument is also contained

in the FHWA's (Federal Highway Administration) Measuring

Instrument Guide.

|

| |

| |

U.S.

Patent : |

US 6,679,106 B1 |

| |

European

Patents : |

No.EP1203928

<Designated States>

England , France , German , Italy ,

The Netherlands |

| |

Japanese

TradeMark : |

NIPPOCTRM |

|

|

|

|

|

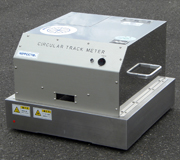

| FRONT VIEW |

BACK SIDE |

|

|

| |

| 1. |

Displacement Sensor

: CCD Laser Displacement Sensor |

| 2. |

Measuring Range of

the Laser : 30 mm (65 - 95) |

| 3. |

Laser Beam Spot Size

: ø70 µm |

| 4. |

Wave Length : 670

mm |

| 5. |

Vertical Resolution

: 3 µm |

| 6. |

Measuring Radius

: 142 mm |

| 7. |

Number of Samples

: 1,024 per revolution |

| 8. |

Sample Spacing :

0.87 mm (± 0.05 mm) |

| 9. |

Divides one rotation

into 8 segments and computes the MPD and/or RMS of each

segment. |

| 10. |

Number of Samples

per segment : 128 |

| 11. |

Tangential velocity

: 6 m/min. |

|

|

| |

| 1. |

Small (approx. 13 kgs.)

and Portable |

| 2. |

Short time for a measurement

(approx. 45 seconds) |

| 3. |

Reports MPD and RMS with

good reproducibility |

| 4. |

Easy measurement without

operator influence |

| 5. |

An automobile battery (12V

DC , 24W) is used for power supply |

| 6. |

Four directions of data

can be obtained in one measurement, i.e., driving direction,

perpendicular to the direction of travel, 45° to the

direction of the travel, and the whole circumference.

|

The number of samples per one

rotation is 1,024 (892 mm) which is divided into 8 segments

for the computation of each MPD and/or RMS.

Analysis of the individual segments can be performed to examine

the profile parallel to the

direction of travel (Segments A and E) and perpendicular to

the direction of travel (Segments C and G). The average of

B,F and D,H indicates MPD for 45° to the direction of

travel.

The overall MPD can also be obtained as an average of the

A through H segments.

|

|

| |

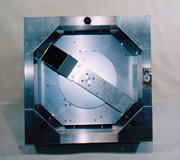

The displacement sensor for this

instrument is a CCD which is mounted on an arm that rotates

at 80 mm above the surface in a circumference of 142 mm radius.

The arm is driven by a D.C. Motor at a tangential velocity

of 6 m/min. The CCD is sampled 1,024 times per revolution

providing a sample spacing of 0.87 mm by an A/D converter.

The data are recorded in memory in a notebook computer. The

data are segmented into eight 111.5 mm arcs of 128 samples

each. The computer software computes the MPD and/or the RMS

of each segment. Optionally the MPD and RMS can be computed

for the middle 100 mm of each segment.

Schematics

of the measuring system

|

|

|

|

Sidewalks,

pavements, floor surfaces of buildings, sports facility floors,

etc. |

|

| |

C. T. Meter :

400mm (W) x 400mm (L) x 270mm (H)

13 kgs.

With Carrying Case :

470mm (W) x 590mm (L) x 330mm (H)

24 kgs.

|

|

| |

|

|

|